Back in 2018 I built my own record cleaning machine. It did the job, but wasn’t pretty.

I recently acquired a better donor turntable and have built a new machine, addressing some of the annoying quirks of my original.

My original article describes the building and operational principals of the first PlecRec record cleaning machine. I will refer to this as the “mk I” for the rest of this article. It’s worth a look because this builds on that design.

The donor for the mk II is an Aiwa PX-E860, acquired for the small sum of £5 from a charity shop. It looked like it had never actually been used. The drive belt was still secured to the platter with the tape used for transit and had never been fitted to the motor pulley. Cosmetic damage to the lid had probably been caused in transit or storage.

It did not work, however. The problem turned out to be a failed primary winding on the mains transformer. I removed this and replaced it with a DC socket for connection of an external DC power supply. Given that there is water slushing around a record cleaning machine this was going to be part of the master plan anyway. For the hell of it I tried playing an old record on it. Yep. it works now. It’s not a great deck, but certainly a step up from those horrible suitcase things, like what I used for the mk I machine.

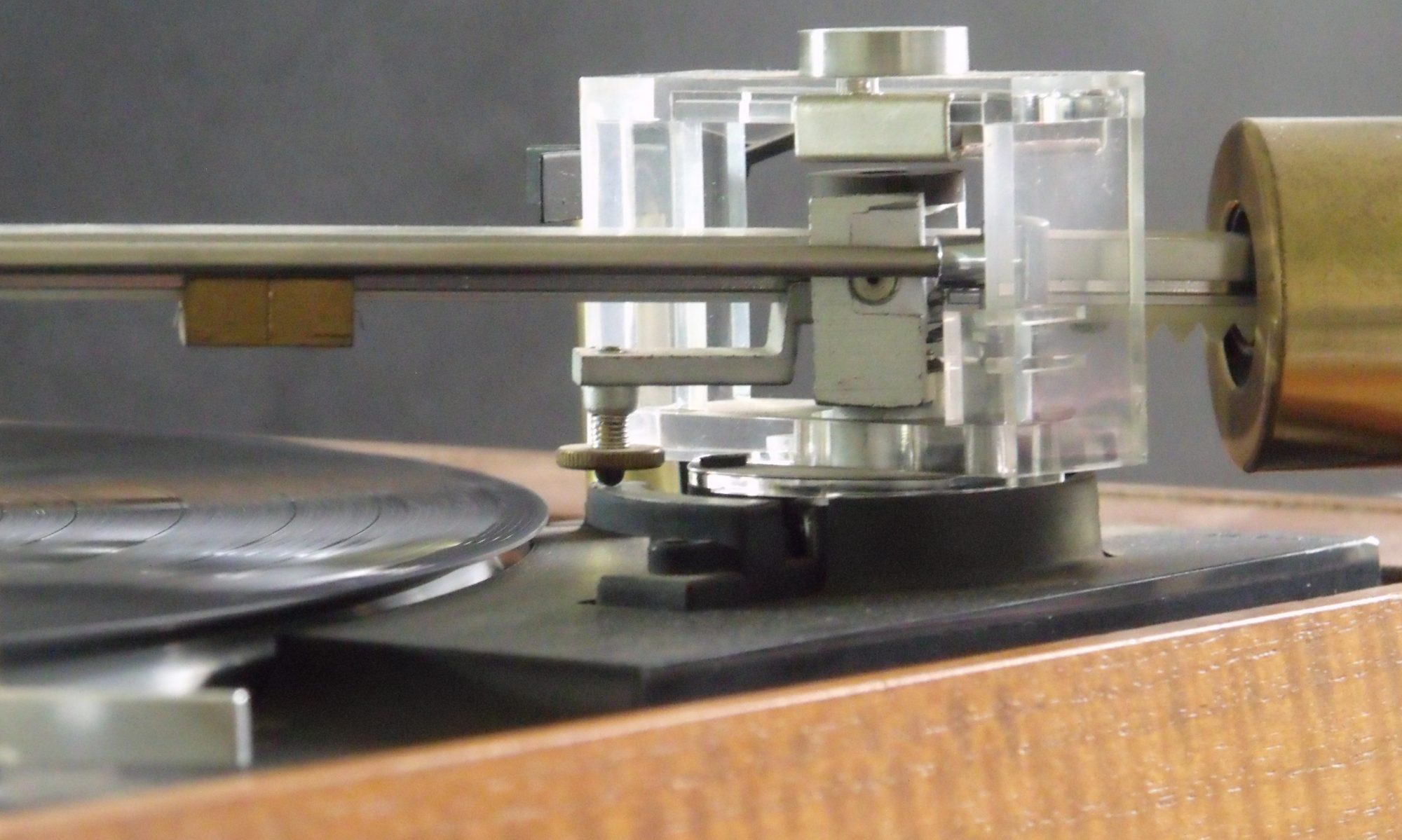

I’ve taken most of the works out. All I need is the motor, turntable and arm pivot. The rest of the automation gears and linkages have come out, along with the arm and cartridge. The motor and platter are a flatter and more torquey alternative to those in the mk I.

The arm was removed and replaced with brass tubing. This is held in place by a friction fit with a short length of silicon tubing.

Internal plumbing consists of just a short length of thin pipe to ensue flexibility. A loop in the pipe to allows for free movement. An aquarium pipe connector glued to a hole in the back interfaces to the suction tube outside. The suction pump and trap from the Mk 1 are retained.

The suction head is made from a Teflon De-soldering pump tip. I have cut it short and drilled a hole in the side. Assembly onto the arm is just done with the hot glue, careful applied.

This brush is just the job for spreading the cleaning fluid, prior to vacuuming off.

The whole set up is now a lot neater. The turntable runs flat and has a bit of torque behind it. Operation is manual for now, but the turntable design lends itself to possibly driving the arm from underneath with a servo. That would enable me to fully automate the whole cleaning processin the future.

For now I’m enjoying the improvement in usability over the Mk 1.

Look out for the Mk III if i do figure out how to fully automate it.