By combining induction techniques for torque and synchronous operation for speed precision, Garrard produced a motor which was revolutionary for its time.

An unfortunate moment of butter fingers led to the demise of this one when I dropped the turntable it was inside. Weighing in at 3/4 of a kilo it fell hard. Hopefully I can fix it.

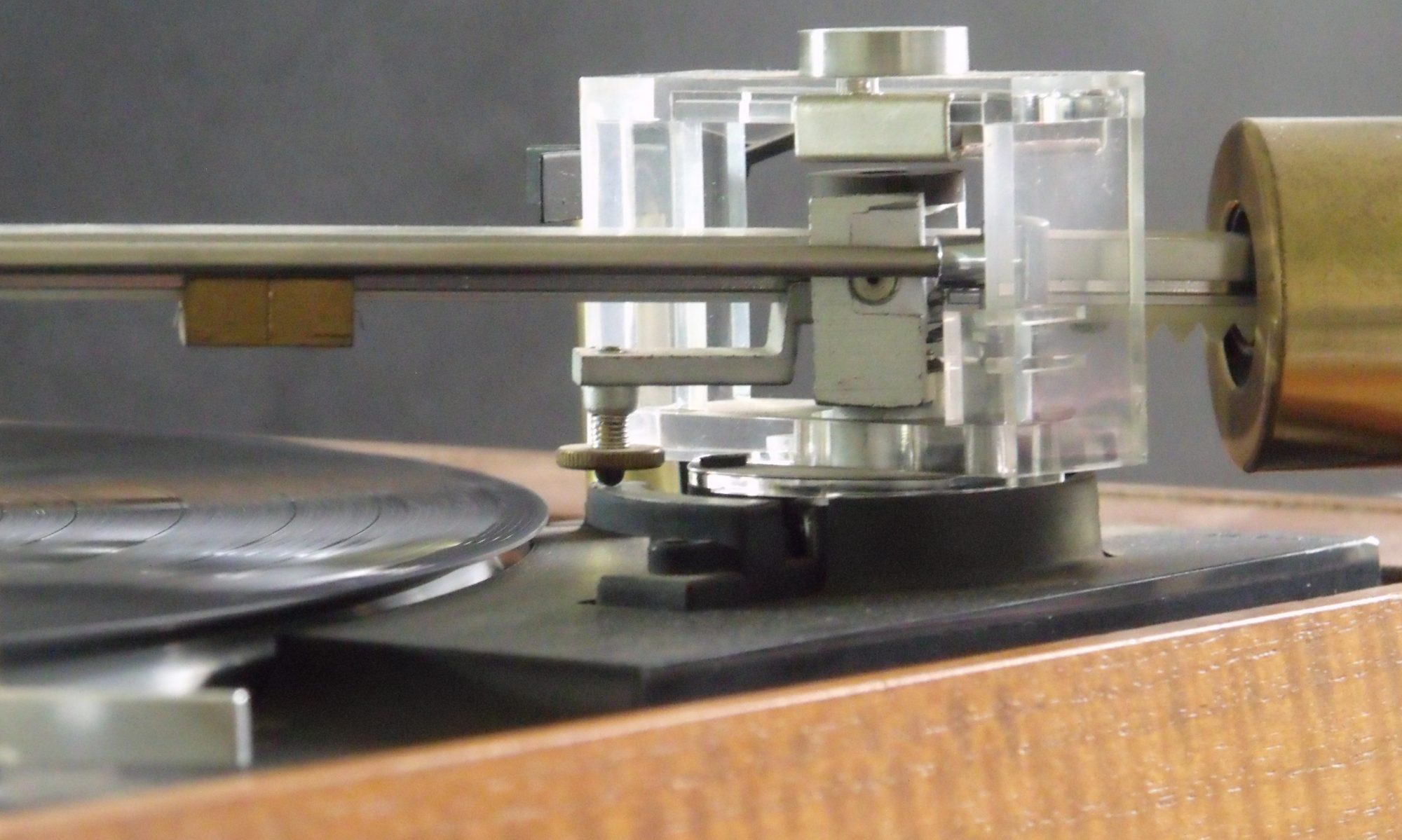

Prior to the accident this motor ran beautifully. Smooth, quiet and bang on speed. Plenty of torque available to turn the rather hefty 2.3 Kg platter of the Garrard Zero 100SB turntable from which it came. After the accident the motor wobbled, made a horrible scraping noise and ran slow and hot. Not a great look for a precision record player.

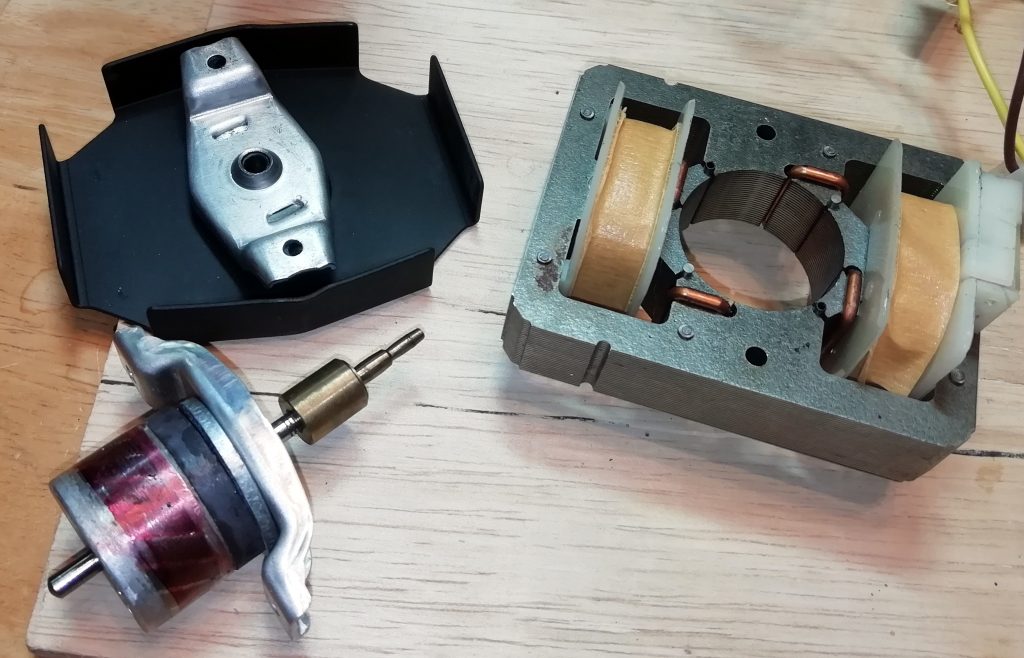

Removal from the turntable was easy. It’s held in place by just 3 cir-clips and connected by three wires. Just 2 bolts held the whole motor together. From my university studies of Electrical Engineering I know how induction motors work, and I know how synchronous motors work. I’ve never seen a motor that claims to do both. Looking at the stator we see a pretty standard shaded pole induction motor. The dual coils make for a 4 pole rather than 2 pole motor for smoother running. They also accommodate 110V by connecting in parallel or 220V if in series.

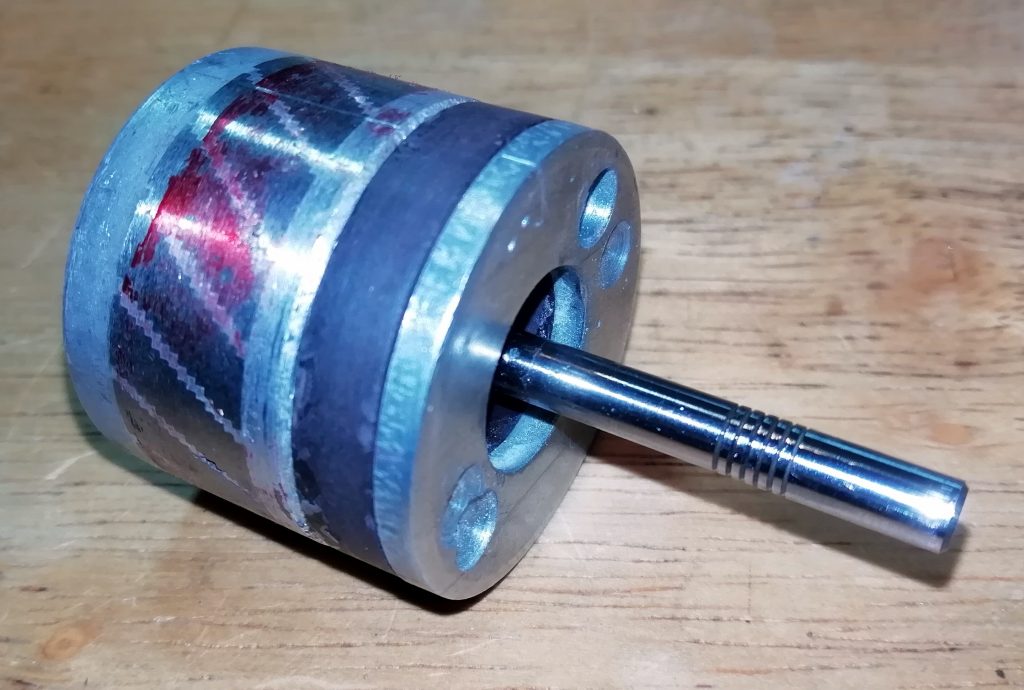

The rotor is interesting. It’s also the broken bit in this case. On the left we see the usual squirrel cage rotor associated with induction motors. So far, so normal. However, above that on the shaft is a grey disk. This is a permanent magnet. This magnet is the “synchronous” part of the motor. The final part is a balance ring. It’s main purpose is to provide a means of balancing the motor mechanically. During manufacture holes are drilled in this and the base ring of the rotor so that it runs without shaking. Much like the wheels of a car are balanced when you have the tyres changed. This having come adrift explains why the thing is running rather rough.

The fix was to dis assemble the rotor, clean it up and put it all back together. Care is needed to get the ring back in the correct orientation to ensure balance is restored. The clue here was observance of the pattern left by the broken glue and using this to establish the correct position.

I marked the outside of the parts with a sharp scribe, as can be just seen in this picture, so I could superglue them back together in alignment. If only it was that easy! First attempt I missed, so I had to remove the disc again with brute force. The magnet snapped off, so that had to be cleaned up and glued back on as well. On the second attempt I had a neatly assembled and balanced rotor.

The motor went back together easily. The top and bottom bearings were lubricated with light motor oil, which is able to handle the relatively high temperature that this sort of motor runs at. Two bolts hold it all together and re assembly in the Zero 100SB turntable was a couple of minutes work.

The motor runs smooth, powerful and at speed again. All that remains now is to re assemble the whole turntable, test and adjust. Hopefully I won’t discover any more problems.