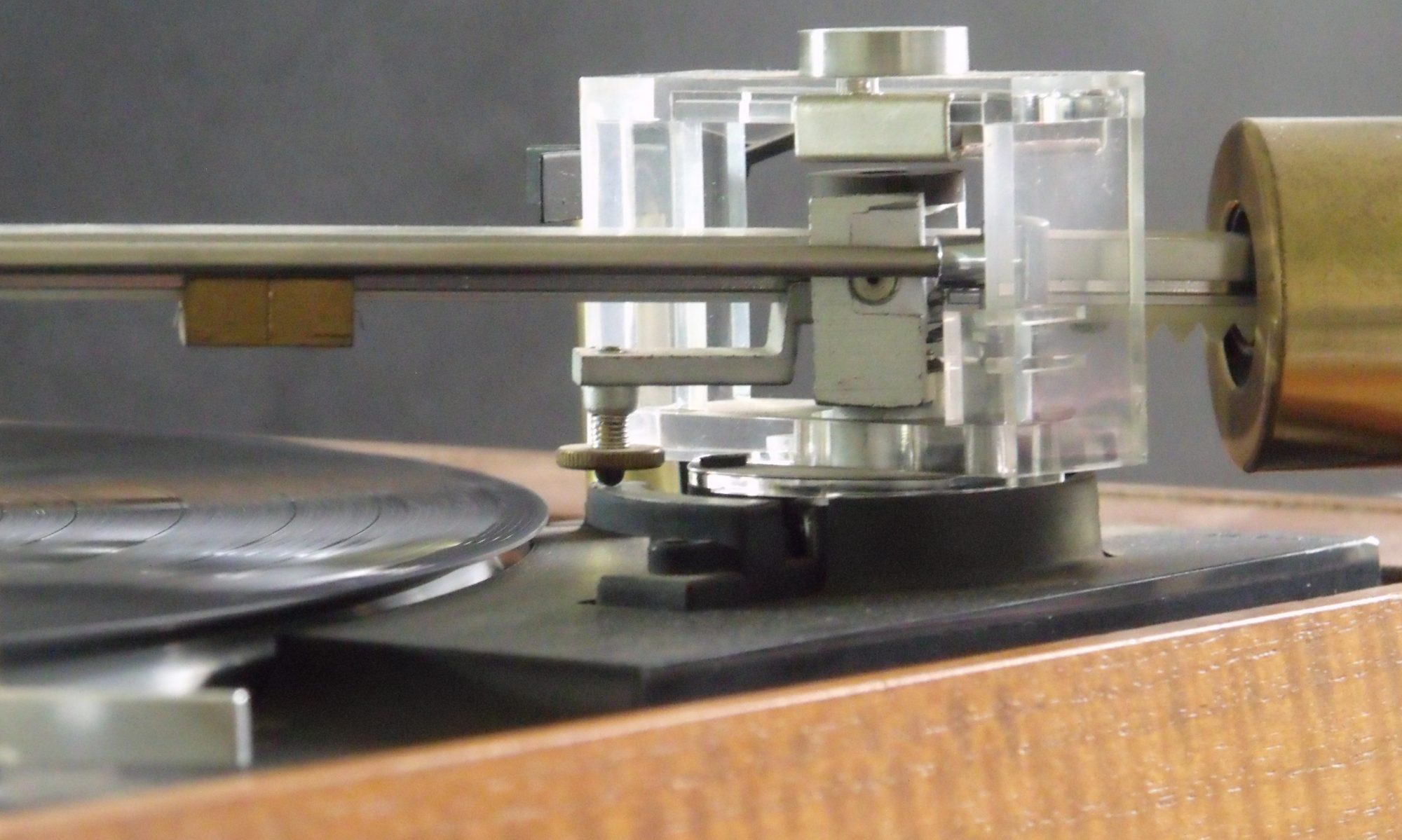

My Sony WM-EX662 Cassette Walkman just doesn’t seem to work as well as my similar WM-EX550.

It has had a belt change, but still suffers from flutter. Recently it has also developed problems with the controls. This turned out to be complex to understand, but easily fixed.

The speed problem was quickly solved by replacing the belt again. On closer inspection the original “replacement” belt was the wrong size. It was actually the same length as the original belt, which I removed because it was stretched and had lost it’s bounce. The belt now fitted was from a Slovakia based eBay trader, whom I have found to be very good. It is slightly shorter and works well.

The trickier problem is the logic control. Pressing the stop button doesn’t always stop it. Quite often it just reverses direction, or even puts it into fast forward. My first line of attack was to open it up and clean the switches as best I could with contact cleaner spray and IPA spray. This had no effect. I sought advice on the excellent tapeheads.net. Unfortunately the advice was that the switches deteriorate and when they go, It’s pretty much game over. ( More on this later)

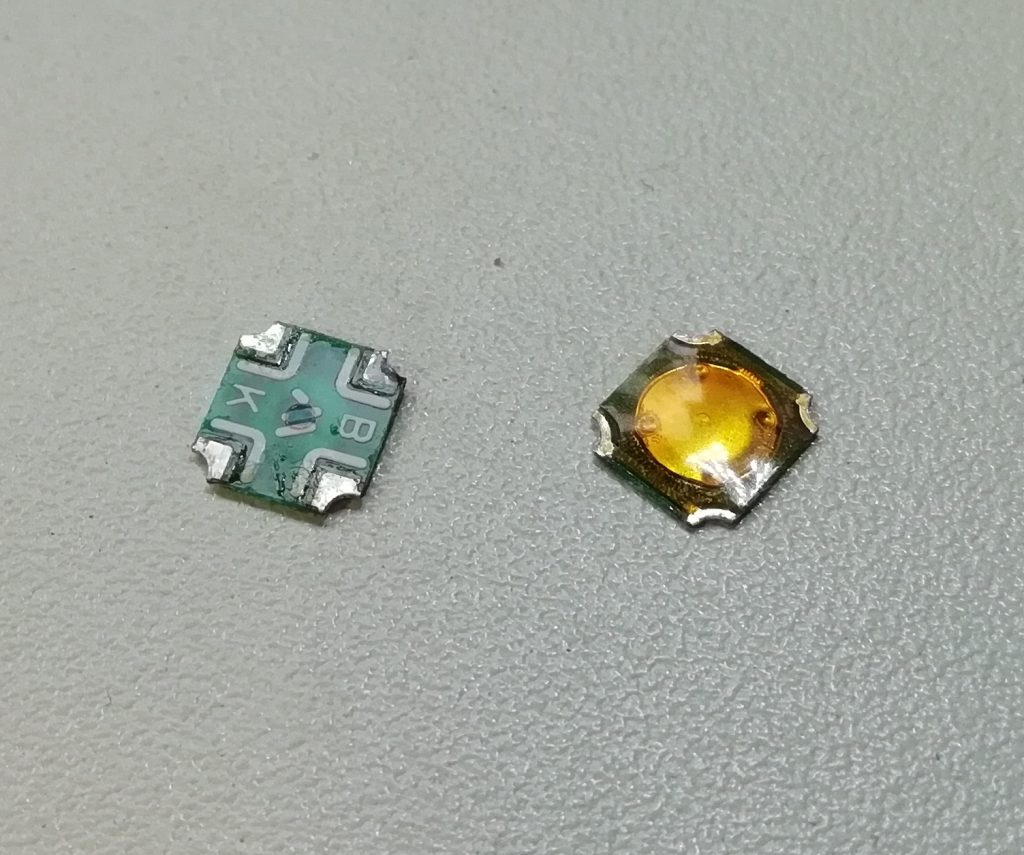

If that’s the case, I have nothing to lose. I’ve ordered some tactile switches from RS components in the hope that they can be dismantled and adapted to fit. However, in the meantime I remembered the Aiwa PX457 that I failed to repair. Sony bought Aiwa at one point, so with a bit of luck they may use the same switch type.

As it happens, the switches in the two machines look the same. it’s got to be worth a try, at the moment neither player works so I have nothing to lose.

Removing the switch was tricky, involving careful coordination with soldering iron, braid and a thin scalpel under the switch. I was able to remove a switch from the Aiwa cleanly. The Sony proved to be easier, probably because by now I had some practice.

The next step was to solder the broken switch back into the Aiwa. Pointless, except for the practice it gave me prior to tackling the Sony.

The tactile switches are tiny, only a few mm across, so great care is needed to solder them back in.

I re assembled the Sony and tested. Nothing. I thought I had fried something and now had two dead units. Then I noticed that the “hold” switch had misaligned on re assembly and was stuck on hold. Re positioning this correctly brought the unit back to life.

After a day or two of correct operation the old faults unfortunately returned. This time I took a more analytical approach and studied the circuit diagram in the service manual.

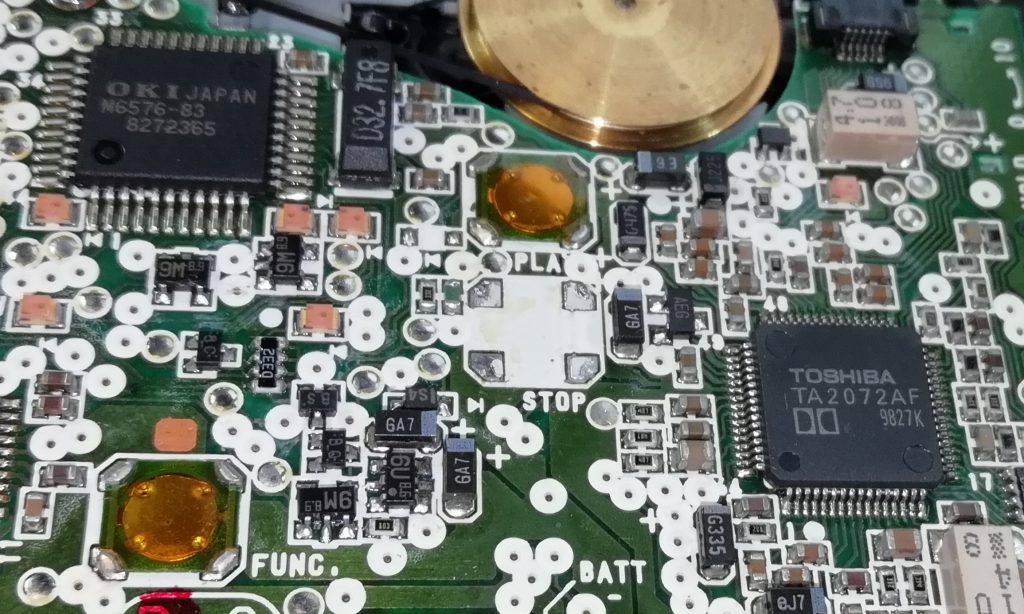

This unit has “logic control” which, means that it contains a small micro controller chip which is pre-programmed with suitable firmware. Various micro controllers are available and the designer will chose one with the features required. This will include the number of inputs and outputs, memory size, speed , power consumption etc. I had expected the control switches to be connected directly controller inputs, perhaps also using outputs to create a “switch matrix”. This is the common design practice found in all sorts of electronic equipment. I actually found something quite different.

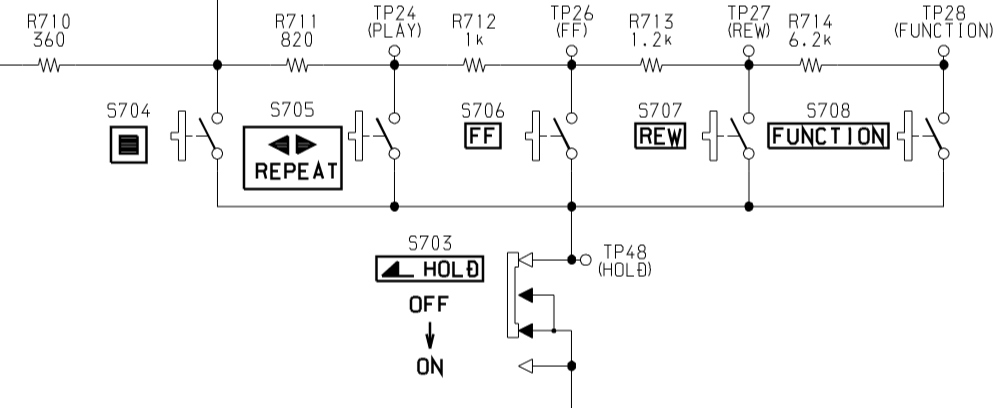

The switches are actually arranged to connect resistors in and out of circuit as they are pressed. R710 on the left connects to a pull up resistor and then to the ADC (Analogue to Digital Converter) input pin on the micro controller. The bottom of the “hold” switch goes to ground.

So:

- With “STOP” pressed the ADC sees 360 ohms.

- With “REPEAT” pressed the ADC sees 360 + 820 = 1.18 K ohms.

- With “FF” pressed the ADC sees 2.18 K ohms

- With “REW” pressed the ADC sees 3.38 K ohms

- With “FUNCTION” pressed the ADC sees a total of 9.58 K ohms.

Each of these combinations will result in a certain voltage at the micro controller input. The internal ADC will turn that into a number that the firmware can use to determine what to do.

When my machine was playing up I sometimes found that the “STOP” button worked like the “REPEAT” button should, and the “REPEAT” button did what “FF” should. It was as if there was too much resistance in the circuit. Now, if the “HOLD” switch was a bit dodgy and wasn’t closing properly, it would behave like a resistor. If that resistor was about 900 ohms, then that would make all the switch functions. behave the way I experienced.

I cleaned the “HOLD” switch. Eureka!

Bad news is that I probably didn’t need to change those tactile switches. Good news is all all good now.