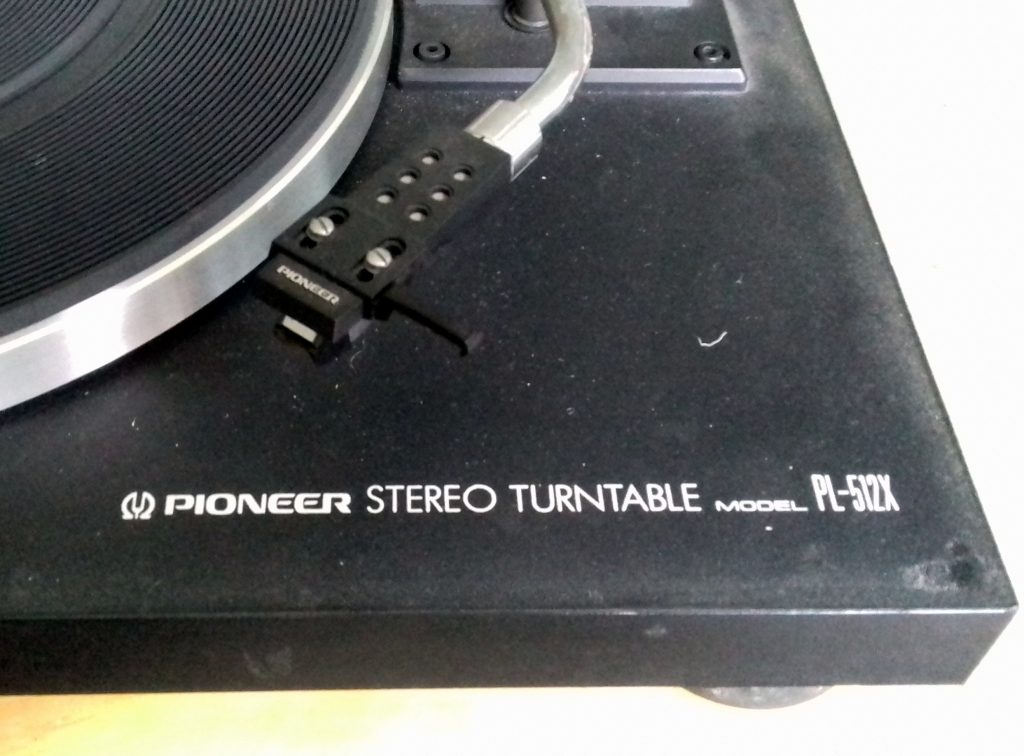

This one was acquired from a local charity shop for £35 in 2017.

It didn’t need much attention, and is in regular use on my second system. I do have grand plans for it though.

Here it is straight from the shop. Initial impressions are good. All is in good condition, particularly the perspex lid. This is important because they can be difficult or impossible to fix and have a big impact on the appearance of a turntable.

The cartridge and stylus look to be the original Pioneer equipment. This is something of a mixed blessing. They are perfectly adequate for use with this unit, and look to be in good condition. The problem is that if you don’t know the provenance it is difficult to know how much wear is on the needle.

In the interest of safety for my more precious records I decided to change it for a nearly new Ortofon OM 5e, which I had left over from another project. I could have fitted it to the original Pioneer branded head shell, however the 512 has a removable shell. I bought a generic metal shell and mounted the Ortofon.

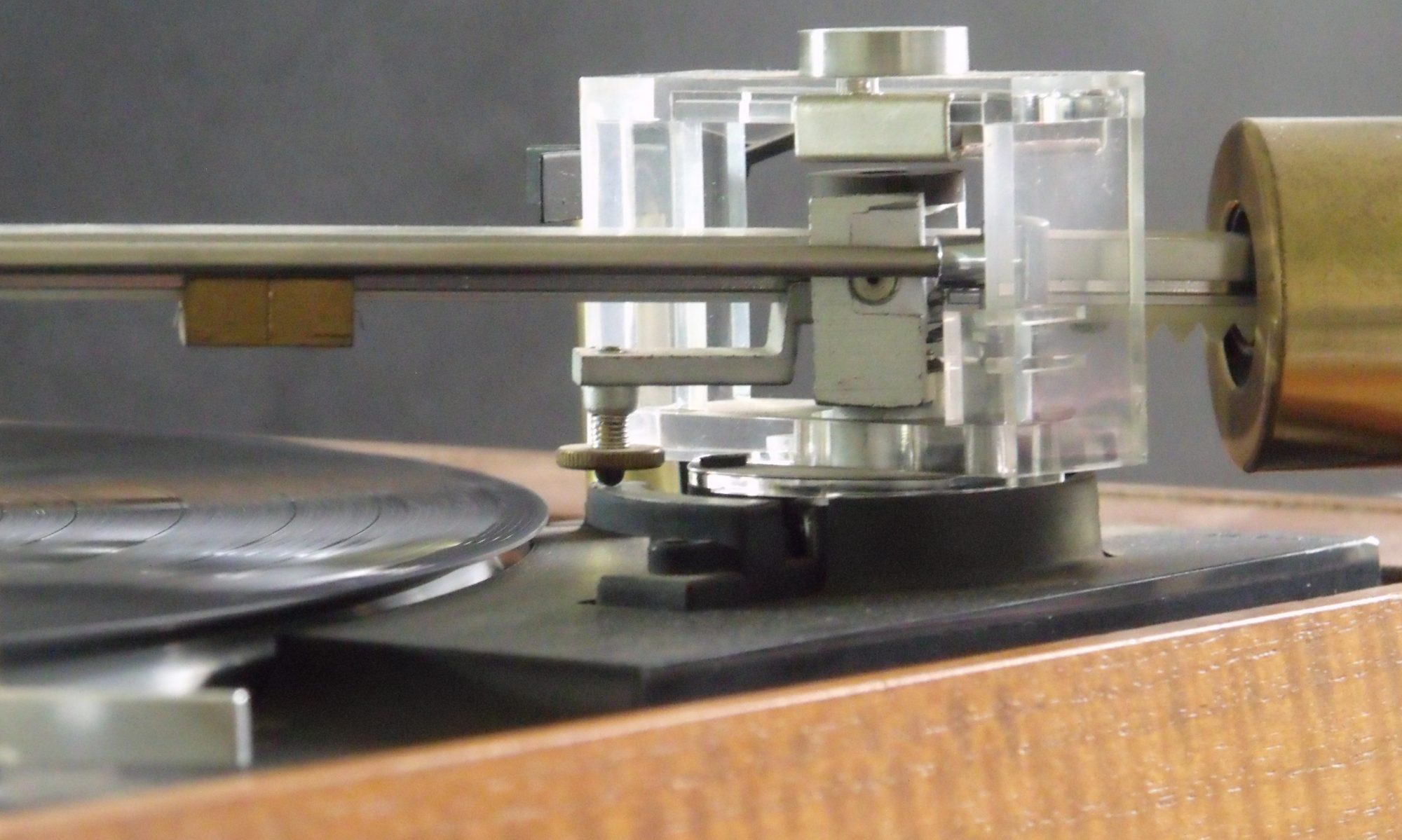

While I was spending money I bought a replacement drive belt. Always worth replacing the belt on an old turntable. The above photo shows how speed is changed on some belt drive turntables.

Looking underneath the turntable and removing the hardboard cover we find all is well.

Electrics are nice and tidy. Looks as new.

This shows the under side of the arm. On the left is the cue lift mechanism. at the bottom is the micro switch which turns on the motor when the arm is removed from rest. The rubber foot top right illustrates the simple, but very effective, means of isolating the plinth from vibration.

This turntable sounds good and is a treat to use. The one thing which lets it down for me is the black vinyl covered chipboard plinth.

This brings me on to my master plan. I intend to find a nice big chunky piece of decent hardwood and fabricate a new plinth for this. It will be a tricky job because of the need to replicate the various cutouts for the arm, turntable, motor, belt drive, speed change etc. I have seen examples of the chipboard plinth being re covered with veneer, and they look good. Solid wood will look great. That job is on the back burner for now though, until I find my wood.